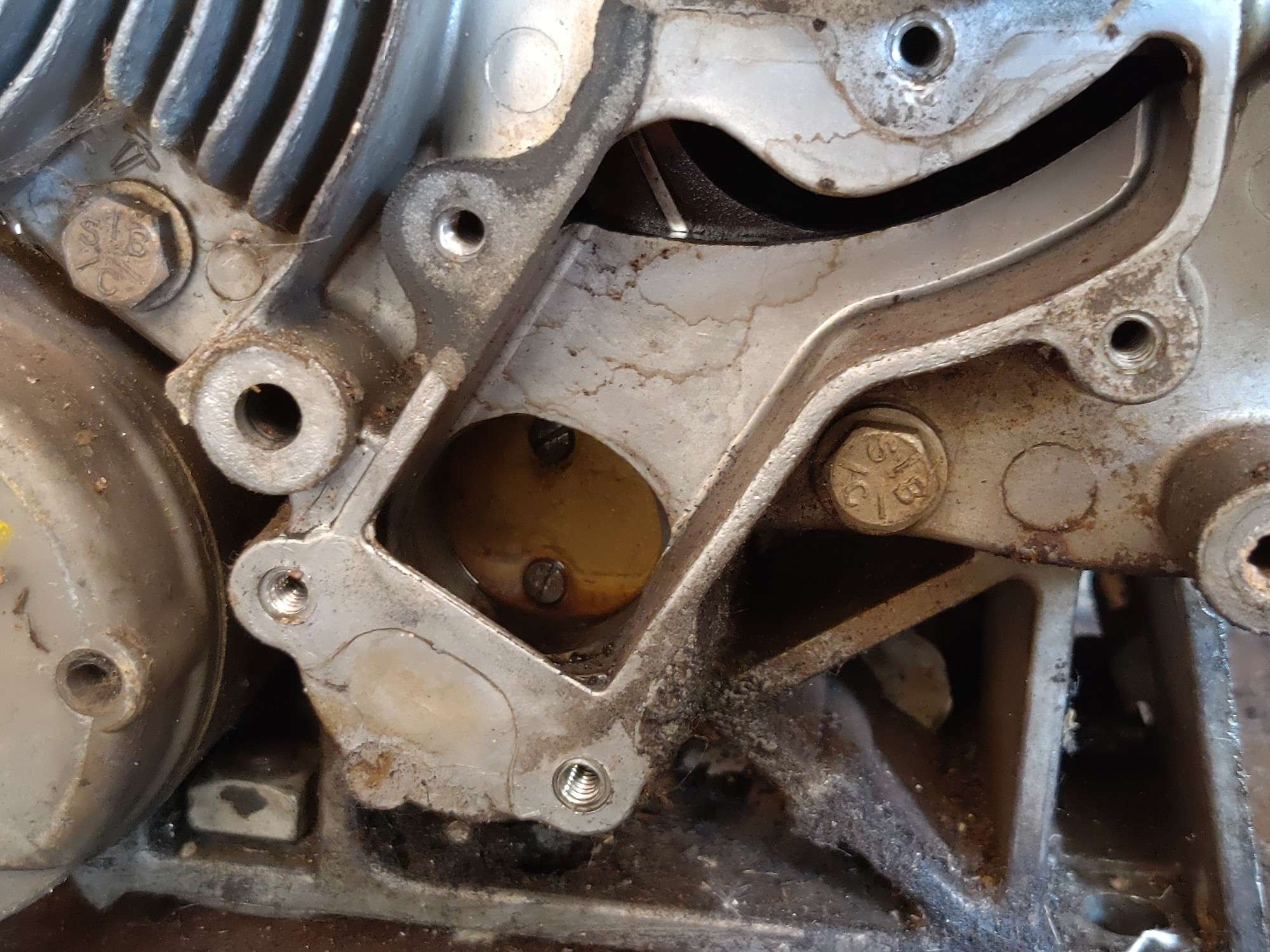

Day oneIt's missing the carb, power pack, coil, and rectifier, but it at least still has all the wires attached and the stupid rare plug. It's clearly been sitting for a while but it's not in bad condition. A mouse or something had also made its home inside the fan shround at one point too For the most part the manual walks ya through it pretty well, mostly just unbolting things, only time i had to get creative was with the flywheel nut, where i had to put a pipe wrench on the cvt and hit a crecent wrench on the nut with a hammer to get it off since an impact socket wouldnt reach that far down the shaft

The rotor was coated with carbon and has one very small spot on the face with some pitting, but I don't think it will be that big of a deal in the long run seeing how nice of condition it looks overall. Most of the seals came out no problem but I'm gonna let it sit overnight in simple green due to a few being rather stuck in there.

After I get everything cleand and all the seals sealing as they should I'll put the housing back together, and sometime wayyy in the future I'll have to take the secondary apart and tap a bolt into the hole. After that it's just a matter of getting a few parts Day twoGot all the seals and springs out of the rotor and am now letting it sit overnight in degreaser after scrubbing a lot of the carbon off'a it. Theres a small chip in a non compression part of the housing but I do not belive that this will cause any problems.

Day threeCleaned and lubed everything and slapped the whole housing assembly together. Compression kinda feels better but upon torquing the through-bolts I stripped out one of the nuts. I'n not sure if it's just because of the metal being old or if my torque wrench is bad but I'll probably buy some new bolts for this anyways |